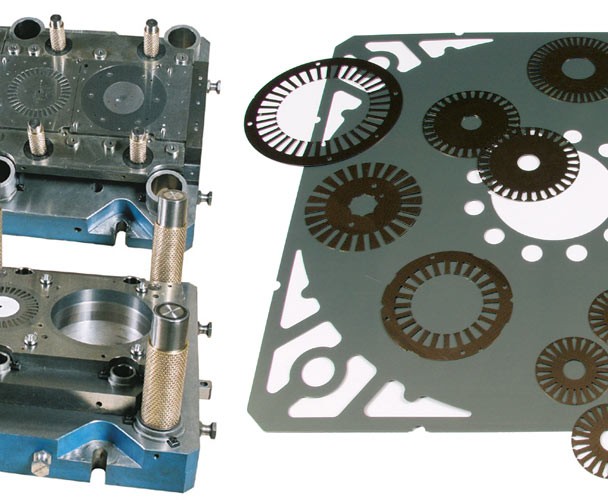

In today’s widely used in sheet metal mold manufacturing, before starting production of the system or part of a product, it is necessary to improve the design drawings and calculations are performed in computer speed and efficiency. sheet metal If manufacturing molding, requires very repetitive and variables depending designs, an approach called parametric design name, the computer for making the support, two or three dimensional parametric and interactive drawing and modeling that can design programs are used. Sheet metal molding of computer-aided design programs, the designer; to be completed as soon as possible in the design, minimization of errors, provides significant advantages such as improving the design quality. When the mold design considering the process, in order to fulfill its seamlessly task pieces working with each other, first after correctly performing the required calculations, of those dimensions is complete and must be fully transferred to the drawing. Varieties suitable for the desired pattern in the sheet metal sheet products before molding by our experienced team will be selected. Customers’ requests in this election, criteria such as quality costs taken into account. Then we prepare our customers as requested by reviewing mold together or if deemed necessary by making recent changes are delivered to our customers. In addition, “it is learned on the job” with all technical personnel received a firm understanding of passes on the corresponding position after the training workshop. Developing, growing, confident future, contributing to the social development of society, to be the leading company in its sector in the global market is the goal of Mold Mould companies.