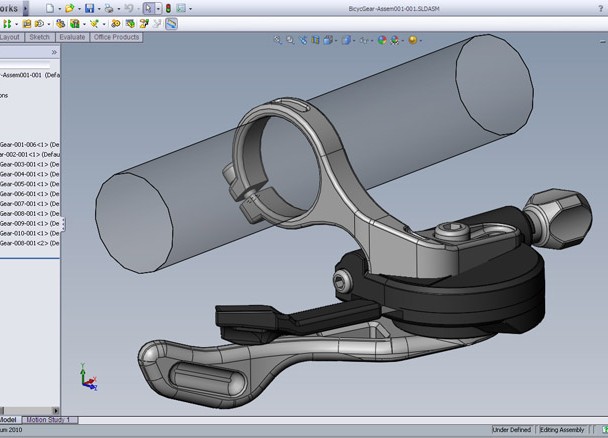

Mold mold so far has produced molds for products in different weights. Who closely follow the mold technology, our company CAD-CAM expenses such as electromagnetic turntable operator errors in the design, use systems to improve production quality and speed. In SolidWorks 2013 CAD software for mold production, CAD-CAM programs for the bodies of the many benches that are required for DELL workstations and mold making is available. Once the mold production process customer requests and demands for design input requirements are determined and considered appropriate steel selection, runner type is determined. Then file with the given work order prepared molds and production begins. During the mold design is done by reviewing the design many times. Customer after the check is transferred to the mold design CAD-CAM department. CAD-CAM design software and is located in the CAM section is done by using the BOB CAM designers. Starting from basic drawing commands of the CAD-CAM is primarily dominated by people on the line to try to develop and are implemented with other SolidWorks drawing and editing commands. Is a program that can answer all of your SolidWorks design application for the manufacturing sector. Installation and finite element analysis simulation and analysis such as strength due to various engineering calculations related material can minimize the margin of error in addition to the CAD-CAM design applications. Product design, mold design and machine design is appropriate to. Engineers or technical staff to support the construction of the information with the SolidWorks software provides the ability to expand the working area to cover many sectors, they can come to a position to handle parts using CAD-CAM program. The designs created in a computer simulation whether these decisions will still be controlled by the processing stage and G-code for CNC machines are created with computers for processing.